-

Description

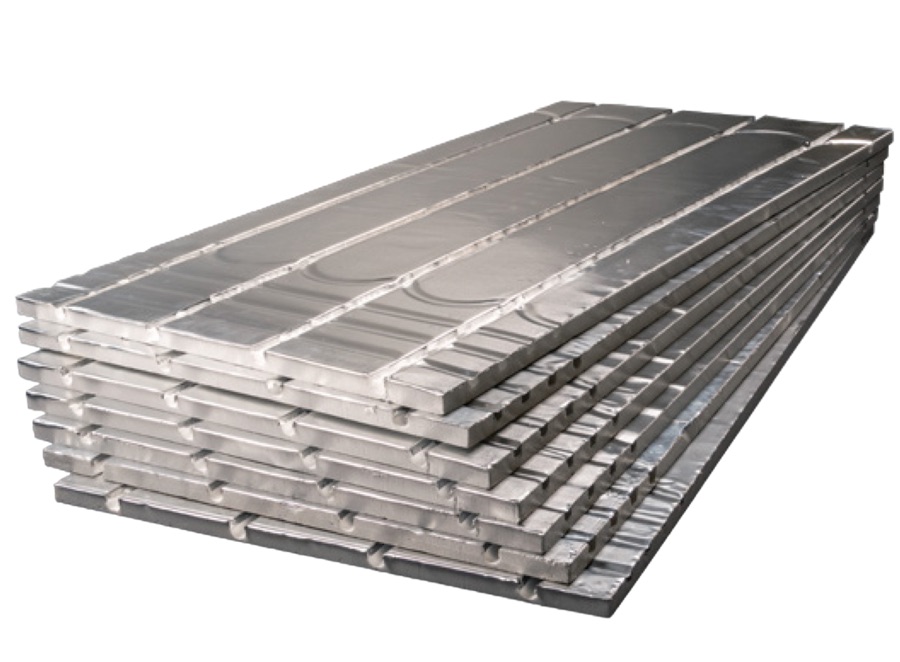

25mm XPS300 overlay board without aluminium foil for 16mm pipe.

- Dimensions: 1200mm × 600mm × 25mm (covers 0.72m² per board)

- Material: High-density extruded polystyrene (XPS) foam

- Compressive Strength: 300kPa – Robust load-bearing capability for residential and light commercial floors (handles foot traffic, furniture, etc., without significant compression)

- Thermal Conductivity (λ): Typically 0.034–0.035 W/(m·K) – Strong downward heat loss reduction for efficient UFH performance

- Surface: Plain / uncoated or basic finish (no aluminium foil heat-spreader layer) – Ideal for setups requiring direct screed, self-levelling compound, or adhesive tile bonding

- Grooves: Precision pre-routed channels optimised for 16mm underfloor heating pipe (standard 150mm centres with smooth radius returns for easy looping and minimal pipe stress)

- Design: Grooved only – No pre-installed heating circuit/pipe, no foil (flexible for custom layouts and dry/wet systems)

- Benefits at a Glance: Low build-up height, lightweight, closed-cell waterproof structure, high compressive strength for durability, quick install – push pipe into grooves (no clips needed in most cases), then cover with levelling screed or tiles.

Suitability:

- underfloor heating installations on concrete/screed bases, or retrofit projects.

- where minimal floor height increase matters, and foil isn’t required (e.g., under).

Installation

Boards must be bonded to the subfloor. Lay in a staggered brick-bond pattern, insert 16mm PEX/PE-RT pipe into channels, apply primer, then self-levelling compound, and final floor covering for a fast, solid system.

- Manuals

-

Specifications

- Dimensions: 1200mm × 600mm × 25mm (covers 0.72m² per board)

- Material: High-density extruded polystyrene (XPS) foam

- Compressive Strength: 300kPa – Robust load-bearing capability for residential and light commercial floors (handles foot traffic, furniture, etc., without significant compression)

- Thermal Conductivity (λ): Typically 0.034–0.035 W/(m·K) – Strong downward heat loss reduction for efficient UFH performance

- Surface: Plain / uncoated or basic finish (no aluminium foil heat-spreader layer) – Ideal for setups requiring direct screed, self-levelling compound, or adhesive tile bonding

- Grooves: Precision pre-routed channels optimised for 16mm underfloor heating pipe (standard 150mm centres with smooth radius returns for easy looping and minimal pipe stress)

25mm Plain XPS300 Insulated Overlay Board

£9.79 £8.81 inc.VAT

In Stock

SKU: ZL-XPS300-16

Buy Now - Pay with Installments...

-

Description

25mm XPS300 overlay board without aluminium foil for 16mm pipe.

- Dimensions: 1200mm × 600mm × 25mm (covers 0.72m² per board)

- Material: High-density extruded polystyrene (XPS) foam

- Compressive Strength: 300kPa – Robust load-bearing capability for residential and light commercial floors (handles foot traffic, furniture, etc., without significant compression)

- Thermal Conductivity (λ): Typically 0.034–0.035 W/(m·K) – Strong downward heat loss reduction for efficient UFH performance

- Surface: Plain / uncoated or basic finish (no aluminium foil heat-spreader layer) – Ideal for setups requiring direct screed, self-levelling compound, or adhesive tile bonding

- Grooves: Precision pre-routed channels optimised for 16mm underfloor heating pipe (standard 150mm centres with smooth radius returns for easy looping and minimal pipe stress)

- Design: Grooved only – No pre-installed heating circuit/pipe, no foil (flexible for custom layouts and dry/wet systems)

- Benefits at a Glance: Low build-up height, lightweight, closed-cell waterproof structure, high compressive strength for durability, quick install – push pipe into grooves (no clips needed in most cases), then cover with levelling screed or tiles.

Suitability:

- underfloor heating installations on concrete/screed bases, or retrofit projects.

- where minimal floor height increase matters, and foil isn’t required (e.g., under).

Installation

Boards must be bonded to the subfloor. Lay in a staggered brick-bond pattern, insert 16mm PEX/PE-RT pipe into channels, apply primer, then self-levelling compound, and final floor covering for a fast, solid system.

- Manuals

-

Specifications

- Dimensions: 1200mm × 600mm × 25mm (covers 0.72m² per board)

- Material: High-density extruded polystyrene (XPS) foam

- Compressive Strength: 300kPa – Robust load-bearing capability for residential and light commercial floors (handles foot traffic, furniture, etc., without significant compression)

- Thermal Conductivity (λ): Typically 0.034–0.035 W/(m·K) – Strong downward heat loss reduction for efficient UFH performance

- Surface: Plain / uncoated or basic finish (no aluminium foil heat-spreader layer) – Ideal for setups requiring direct screed, self-levelling compound, or adhesive tile bonding

- Grooves: Precision pre-routed channels optimised for 16mm underfloor heating pipe (standard 150mm centres with smooth radius returns for easy looping and minimal pipe stress)

Related products

20mm Foil Coated XPS400 Insulated Overlay Board

£11.89£10.70 inc.VATLarsen Levelling Compound – Lartex Flow Bag & Bottle 0-10mm

£25.14£22.63 inc.VATRapid Bond Spray Adhesive for UFH Overlay Boards

£11.49£10.34 inc.VATUltraplan Renovation Levelling Screed 25kg

£24.99£22.49 inc.VAT