-

Description

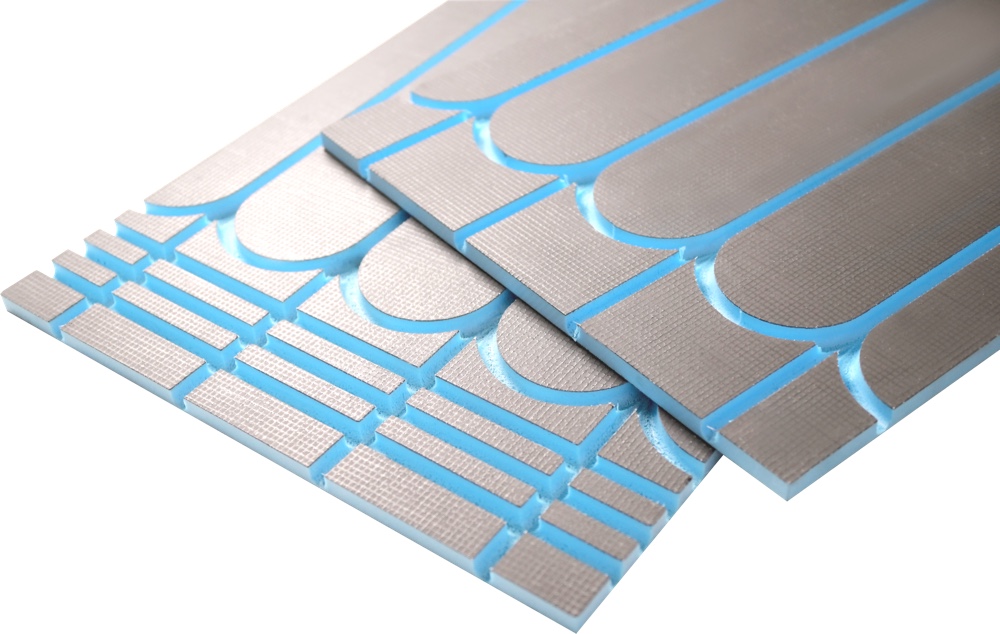

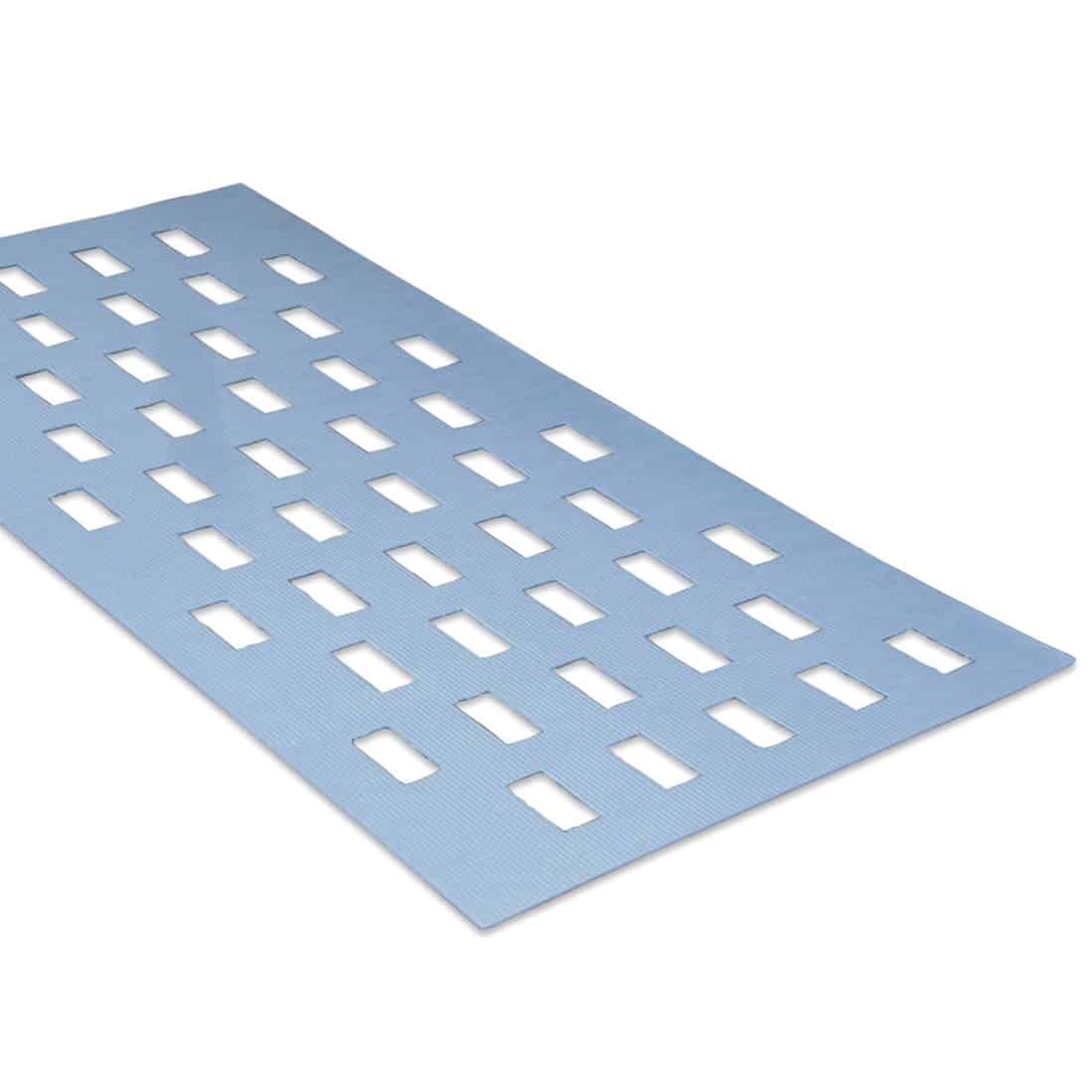

Our premium cement-coated XPS boards for retrofit water underfloor heating systems. These overlay boards are made from 300kPa high-density XPS foam which is thermally insulating, lightweight, waterproof, and faced with a reinforced cement coating.

The boards offer a quick and easy solution for the placement of pipework in both domestic and commercial underfloor heating applications. The lightweight, reinforced cement facing provides a robust surface that is ideal for direct bonding of tiles. Many other types of finish, such as engineered wood, carpet, vinyl, etc., can also be used with additional preparation of the panels.

These panels are ideal for installation on solid floors, such as concrete, screed and asphalt floors, as well as suspended timber floors that have been boarded with suitable floor boarding, such as tongue-and-groove planking or chipboard planking.

The panels are easy to cut and install and should be laid with the panel joints staggered in a brick bond style. The routed channels are compatible with flexible low-pressure underfloor heating pipe. The panels are designed for use over existing floors, providing a low-height build-up and insulated floor.

Each cement ocated XPS panel measures 1200 x 600 x 20mm and takes a 15 or 16mm pipe at 150mm pipe spacings. Each are pre-formed with straight runs, return loops and cross runs at one end, and covered with a 3mm layer of concrete.

The panels can be laid onto any existing, level flooring and should be fixed securely using standard tile adhesive.

PLEASE NOTE: due to fragility this product has to be shipped by pallet.

Flooring Advice:

Laminate/Engineered wood

Cover boards with a 3mm breathable underlay then float the floor planks straight over. Use a floor sensor to stop overheating and damage to the wood.Carpet/Vinyl

Prime the surface and pipe runs, then cover with a self leveller between 5-10mm. Alternatively, cover with thin wooden sheets not exceeding 6mm. The carpet & underlay combined should not exceed 2tog rating.Tile/Stone

Prime the surface and pipe runs then tile directly onto the boards using an S2 rated Flexible Tile Adhesive.Maximum pipe length:

- 20mm panel = 100m

- Manuals

-

Specifications

Panel Details:

• High density cement coated XPS300 floor heating panel

• Pre-formed channels, returns and turns

• 20mm panel designed for 16mm pipe

• Channels at 150mm pipe centres

• Dimensions: 1200mm x 600mm x 20mm

• Thermal conductivity: 0.033m²k/w

• Temp Range: -50 to 75C

• Panel coverage: 0.72sqm

• Panel Weight: 2.6kgMade of lightweight high density extruded polystyrene

• Easy to fit- can be cut to the desired size with a craft knife or saw

• Includes pre-bonded layer of cement, front and back

• Perfect for retro fit installations

• No need to dig up the floor to install underfloor heating

• No moisture, mess or lengthy drying times typical with screeding

• Very fast warm up timesHeat Outputs- 20mm panel

• Under tiles: 97w/sqm

• Under laminate, wood, engineered: 65w/sqm

• Under carpet, vinyl: 51w/sqmSpecification Performance Product Code ZL-CPS300-16 Board Type Extruded Polystyrene (XPS) Strength at 10% Compression 300 kPa Thermal Conductivity 0.033 W/mK Operating Temperature Range -50°C to +75°C Density (Foam Core Only) 33 kg/m³ Pipe Centres 150 mm Board Size 600 × 1200 × 20 mm Fire Classification Euroclass E Thickness / Weight 20 mm / 2.6 kg Sound Reduction 20 dB Water Absorption by Volume 0.8% (tested to BS EN 12087) Heat Output at 50°C 80 W/m² Recommended Flow Temperature 45°C to 55°C

20mm Cement Coated XPS300 Insulated Overlay Board

£12.72 inc.VAT

How many do I need?

-

Description

Our premium cement-coated XPS boards for retrofit water underfloor heating systems. These overlay boards are made from 300kPa high-density XPS foam which is thermally insulating, lightweight, waterproof, and faced with a reinforced cement coating.

The boards offer a quick and easy solution for the placement of pipework in both domestic and commercial underfloor heating applications. The lightweight, reinforced cement facing provides a robust surface that is ideal for direct bonding of tiles. Many other types of finish, such as engineered wood, carpet, vinyl, etc., can also be used with additional preparation of the panels.

These panels are ideal for installation on solid floors, such as concrete, screed and asphalt floors, as well as suspended timber floors that have been boarded with suitable floor boarding, such as tongue-and-groove planking or chipboard planking.

The panels are easy to cut and install and should be laid with the panel joints staggered in a brick bond style. The routed channels are compatible with flexible low-pressure underfloor heating pipe. The panels are designed for use over existing floors, providing a low-height build-up and insulated floor.

Each cement ocated XPS panel measures 1200 x 600 x 20mm and takes a 15 or 16mm pipe at 150mm pipe spacings. Each are pre-formed with straight runs, return loops and cross runs at one end, and covered with a 3mm layer of concrete.

The panels can be laid onto any existing, level flooring and should be fixed securely using standard tile adhesive.

PLEASE NOTE: due to fragility this product has to be shipped by pallet.

Flooring Advice:

Laminate/Engineered wood

Cover boards with a 3mm breathable underlay then float the floor planks straight over. Use a floor sensor to stop overheating and damage to the wood.Carpet/Vinyl

Prime the surface and pipe runs, then cover with a self leveller between 5-10mm. Alternatively, cover with thin wooden sheets not exceeding 6mm. The carpet & underlay combined should not exceed 2tog rating.Tile/Stone

Prime the surface and pipe runs then tile directly onto the boards using an S2 rated Flexible Tile Adhesive.Maximum pipe length:

- 20mm panel = 100m

- Manuals

-

Specifications

Panel Details:

• High density cement coated XPS300 floor heating panel

• Pre-formed channels, returns and turns

• 20mm panel designed for 16mm pipe

• Channels at 150mm pipe centres

• Dimensions: 1200mm x 600mm x 20mm

• Thermal conductivity: 0.033m²k/w

• Temp Range: -50 to 75C

• Panel coverage: 0.72sqm

• Panel Weight: 2.6kgMade of lightweight high density extruded polystyrene

• Easy to fit- can be cut to the desired size with a craft knife or saw

• Includes pre-bonded layer of cement, front and back

• Perfect for retro fit installations

• No need to dig up the floor to install underfloor heating

• No moisture, mess or lengthy drying times typical with screeding

• Very fast warm up timesHeat Outputs- 20mm panel

• Under tiles: 97w/sqm

• Under laminate, wood, engineered: 65w/sqm

• Under carpet, vinyl: 51w/sqmSpecification Performance Product Code ZL-CPS300-16 Board Type Extruded Polystyrene (XPS) Strength at 10% Compression 300 kPa Thermal Conductivity 0.033 W/mK Operating Temperature Range -50°C to +75°C Density (Foam Core Only) 33 kg/m³ Pipe Centres 150 mm Board Size 600 × 1200 × 20 mm Fire Classification Euroclass E Thickness / Weight 20 mm / 2.6 kg Sound Reduction 20 dB Water Absorption by Volume 0.8% (tested to BS EN 12087) Heat Output at 50°C 80 W/m² Recommended Flow Temperature 45°C to 55°C

Related products

Breathable 2mm Underlay for Overlay Systems – 6sqm

£14.49inc.VATUnderfloor Heating Floor Sensor Probe

£11.99inc.VAT