-

Description

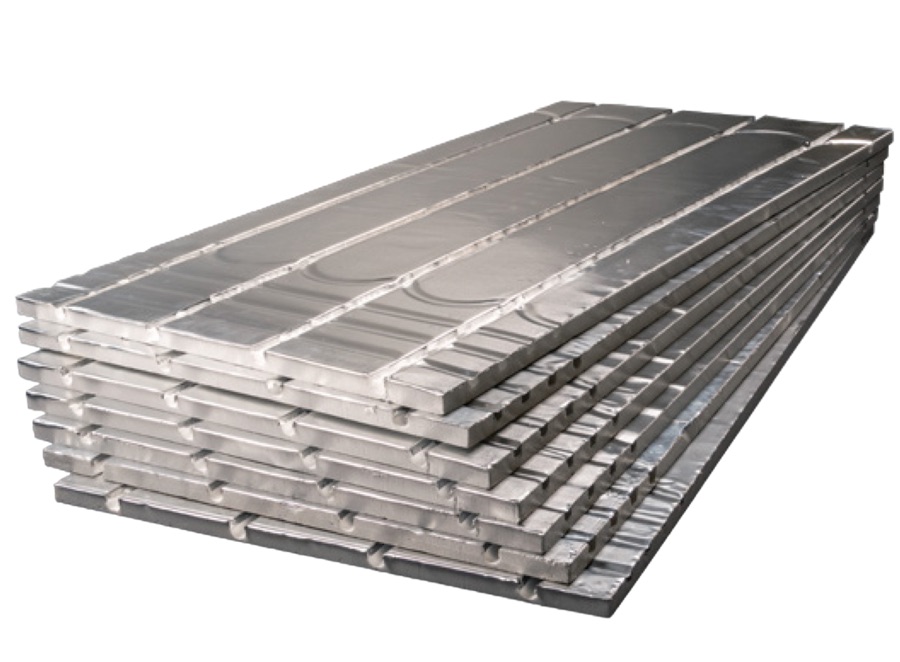

Premium Foil Coated XPS400 Overlay Boards for Water Underfloor Heating

Elevate your flooring with our high-performance foil-coated XPS400 overlay boards — the perfect low-profile solution for installing water underfloor heating in new builds or existing spaces. These lightweight, durable panels minimize disruption while delivering fast, even heat distribution thanks to the aluminium foil surface.

Crafted from premium high-compressive-strength extruded polystyrene (XPS) with a 400 kPa rating, the boards offer excellent thermal insulation, moisture resistance, and structural integrity. The aluminium foil layer reflects and spreads heat quickly across the floor, boosting system efficiency for residential and commercial use.

Key Features & Benefits

- Superior Heat Transfer — Aluminium foil coating ensures rapid, uniform heat distribution for quicker warm-up times and optimal performance.

- Low-Profile Installation — Just 20mm thick, adding minimal height — ideal over existing concrete, timber, or solid subfloors.

- Lightweight & Durable — High-density XPS at 400 kPa provides strength without excess weight; easy to handle and cut with basic tools.

- Quick Pipe Placement — Pre-routed channels accept 15mm or 16mm flexible low-pressure pipes at 150mm centres.

- Versatile Flooring Options — Compatible with laminate, engineered wood, carpet, vinyl/LVT, and tiles.

- Simple Fixing — Secure to clean, level surfaces using Rapid Response Spray Adhesive (or similar).

Each panel measures 1200 × 600 × 20mm and covers 0.72m². Install on level subfloors for a seamless, insulated underfloor heating base.

Important: Due to product fragility, all orders are shipped by pallet for safe delivery.

Adhesive Consumption Guide

- Wood or tiled subfloor — Approx. 5m² per can (spray subfloor only, then lay board).

- Concrete or porous subfloor — Approx. 2.5m² per can (spray both subfloor and board underside for glue-to-glue bond).

Flooring Compatibility & Preparation

Laminate / Engineered Wood

- Install as a floating floor directly over the boards.

- Use breathable underlay if planks aren’t pre-bonded.

- Maximum plank thickness: 20mm.

Carpet / Vinyl / LVT

- Prime surface with Mapei Eco Prim Grip (or equivalent).

- Apply 5–10mm fibre-reinforced self-levelling screed (e.g., Mapei Ultraplan) to fill grooves/channels completely.

- Combined carpet + underlay tog rating: max 2 tog.

Tile / Stone

- Prime with Mapei Eco Prim Grip.

- Apply 5–6mm self-levelling screed.

- Fix tiles using Ultra ProFlex S2 Flexible Tile Adhesive (or similar).

- Maximum tile thickness: 20mm (ideal ≤15mm).

Why Choose These Foil-Coated XPS400 Boards?

- Fast, low-disruption installation over existing floors.

- Excellent heat spread and energy efficiency from aluminium foil.

- Lightweight yet robust (400 kPa compressive strength).

- Works with nearly any final floor covering.

- Suitable for professional installers or confident DIY projects.

These foil-coated XPS underfloor heating overlay boards combine insulation, durability, and performance in a slim 20mm package — perfect for efficient, comfortable heated floors without major upheaval.

- Manuals

-

Specifications

Panel Details:

• High density XPS400 board

• Pre-formed channels, returns and turns

• 20mm board for 15 or 16mm pipe

• Channels spaced 150mm apart

• Dimensions: 1200mm x 600mm x 20mm

• Thermal resistance: 0.035m²k/w

• Each panel covers 0.72sqmMade of lightweight high density extruded polystyrene

• Easy to fit- can be cut to the desired size with a craft knife or saw

• Includes pre-bonded 100 micron aluminium surface

• Perfect for retro fit installations

• No need to dig up the floor to install underfloor heating

• No moisture, mess or lengthy drying times typical with screeding

• Very fast warm up timesHeat Outputs @45c flow temps

• Under tiles: 97w/sqm

• Under laminate, wood, engineered: 65w/sqm

• Under carpet, vinyl: 51w/sqm

20mm Foil Coated XPS400 Insulated Overlay Board

£12.99 inc.VAT

How many do I need?

-

Description

Premium Foil Coated XPS400 Overlay Boards for Water Underfloor Heating

Elevate your flooring with our high-performance foil-coated XPS400 overlay boards — the perfect low-profile solution for installing water underfloor heating in new builds or existing spaces. These lightweight, durable panels minimize disruption while delivering fast, even heat distribution thanks to the aluminium foil surface.

Crafted from premium high-compressive-strength extruded polystyrene (XPS) with a 400 kPa rating, the boards offer excellent thermal insulation, moisture resistance, and structural integrity. The aluminium foil layer reflects and spreads heat quickly across the floor, boosting system efficiency for residential and commercial use.

Key Features & Benefits

- Superior Heat Transfer — Aluminium foil coating ensures rapid, uniform heat distribution for quicker warm-up times and optimal performance.

- Low-Profile Installation — Just 20mm thick, adding minimal height — ideal over existing concrete, timber, or solid subfloors.

- Lightweight & Durable — High-density XPS at 400 kPa provides strength without excess weight; easy to handle and cut with basic tools.

- Quick Pipe Placement — Pre-routed channels accept 15mm or 16mm flexible low-pressure pipes at 150mm centres.

- Versatile Flooring Options — Compatible with laminate, engineered wood, carpet, vinyl/LVT, and tiles.

- Simple Fixing — Secure to clean, level surfaces using Rapid Response Spray Adhesive (or similar).

Each panel measures 1200 × 600 × 20mm and covers 0.72m². Install on level subfloors for a seamless, insulated underfloor heating base.

Important: Due to product fragility, all orders are shipped by pallet for safe delivery.

Adhesive Consumption Guide

- Wood or tiled subfloor — Approx. 5m² per can (spray subfloor only, then lay board).

- Concrete or porous subfloor — Approx. 2.5m² per can (spray both subfloor and board underside for glue-to-glue bond).

Flooring Compatibility & Preparation

Laminate / Engineered Wood

- Install as a floating floor directly over the boards.

- Use breathable underlay if planks aren’t pre-bonded.

- Maximum plank thickness: 20mm.

Carpet / Vinyl / LVT

- Prime surface with Mapei Eco Prim Grip (or equivalent).

- Apply 5–10mm fibre-reinforced self-levelling screed (e.g., Mapei Ultraplan) to fill grooves/channels completely.

- Combined carpet + underlay tog rating: max 2 tog.

Tile / Stone

- Prime with Mapei Eco Prim Grip.

- Apply 5–6mm self-levelling screed.

- Fix tiles using Ultra ProFlex S2 Flexible Tile Adhesive (or similar).

- Maximum tile thickness: 20mm (ideal ≤15mm).

Why Choose These Foil-Coated XPS400 Boards?

- Fast, low-disruption installation over existing floors.

- Excellent heat spread and energy efficiency from aluminium foil.

- Lightweight yet robust (400 kPa compressive strength).

- Works with nearly any final floor covering.

- Suitable for professional installers or confident DIY projects.

These foil-coated XPS underfloor heating overlay boards combine insulation, durability, and performance in a slim 20mm package — perfect for efficient, comfortable heated floors without major upheaval.

- Manuals

-

Specifications

Panel Details:

• High density XPS400 board

• Pre-formed channels, returns and turns

• 20mm board for 15 or 16mm pipe

• Channels spaced 150mm apart

• Dimensions: 1200mm x 600mm x 20mm

• Thermal resistance: 0.035m²k/w

• Each panel covers 0.72sqmMade of lightweight high density extruded polystyrene

• Easy to fit- can be cut to the desired size with a craft knife or saw

• Includes pre-bonded 100 micron aluminium surface

• Perfect for retro fit installations

• No need to dig up the floor to install underfloor heating

• No moisture, mess or lengthy drying times typical with screeding

• Very fast warm up timesHeat Outputs @45c flow temps

• Under tiles: 97w/sqm

• Under laminate, wood, engineered: 65w/sqm

• Under carpet, vinyl: 51w/sqm

Related products

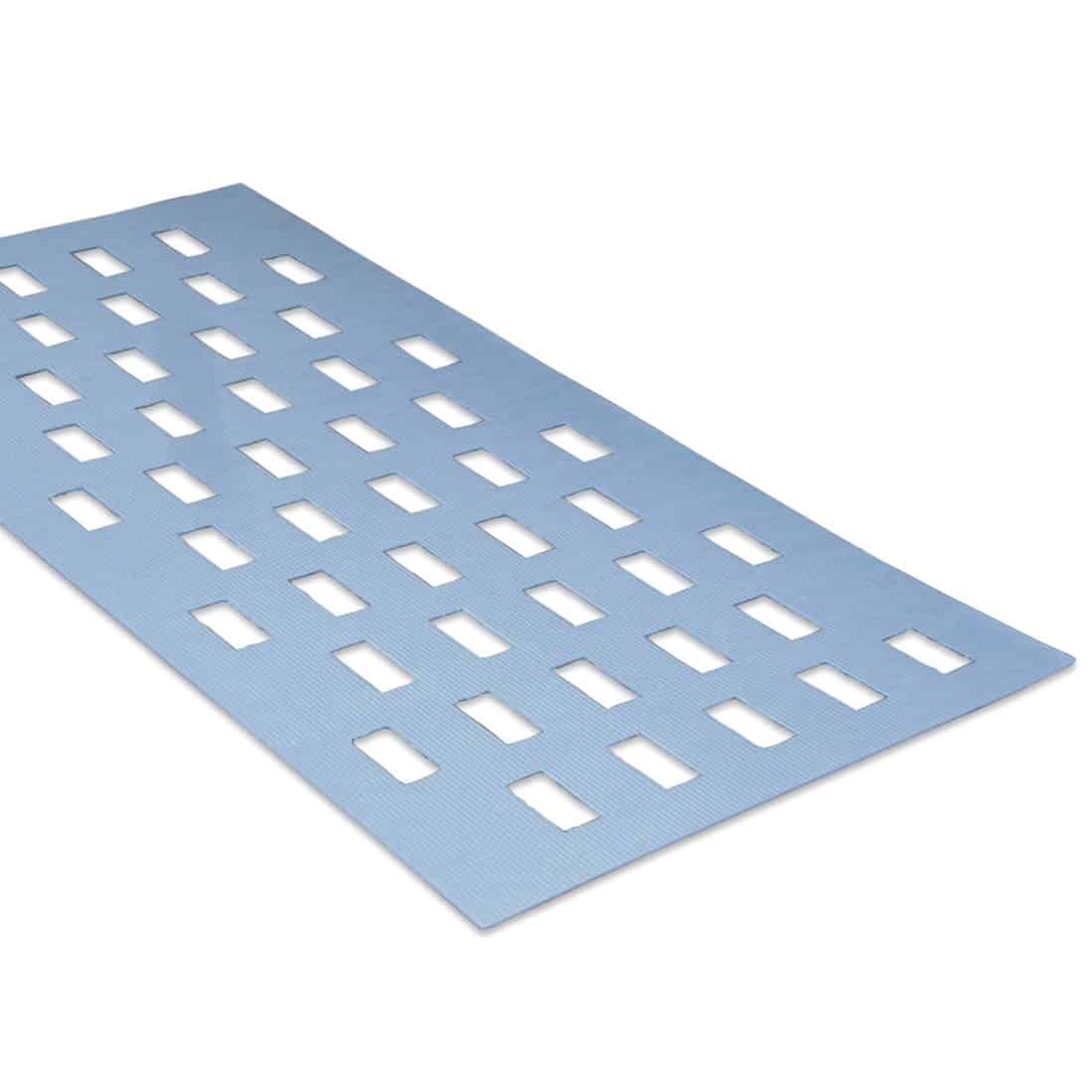

Breathable 2mm Underlay for Overlay Systems – 6sqm

£14.49inc.VAT