Water Underfloor Heating over Existing Floors

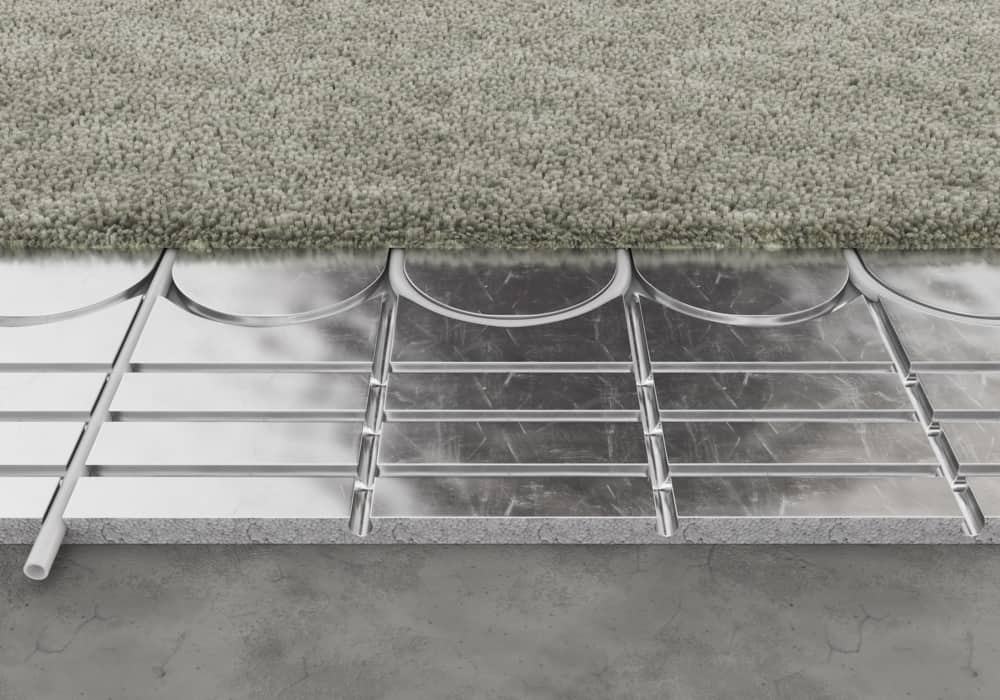

If you have a retrofit project or need to make underfloor heating work for floors you already have, then an overlay system might be the ideal solution. Overlay systems are one of the most underrated types of water underfloor heating system available today. They are a great option for both new builds and existing properties, but are most popular as retrofit systems. Too many people incorrectly assume that unless they can accommodate an in-screed installation, then they cannot install water underfloor heating. This is simply not true. Overlay systems are versatile and almost universal to every type of property. They don’t require the floor to be dug out and are simply laid down onto the existing floor.

The existing floor is best prepared by covering with a shallow self levelling screed to give a perfectly level surface. The boards are then bonded to the floor and the pipes inserted into the grooves. Depending on the flooring you wish to lay down will determine how the surface of the boards are finished. Overlay systems are more efficient and effective then joist systems, and has the faster response out of all three system. The only downside to them is that they can be expensive and, most importantly, they will raise the floor height, but only up to 25mm. If you want to install water underfloor heating in your home and can accommodate the floor height increase, the overlay system is by far your best choice.

Pro Tip: Pick one of the 3 different finishing methods for water underfloor heating overlay systems – great for retrofitting – for your floor…

Wet Underfloor Heating – Under wood |

|

Wet Underfloor Heating – Under tiles |

|

|

|

Which kit should you choose?

Now you have decided on your floor construction and learnt about the different fixing methods, is your project for a singe room or multiple rooms?

|

Single Room System > |

Multi Room System > |

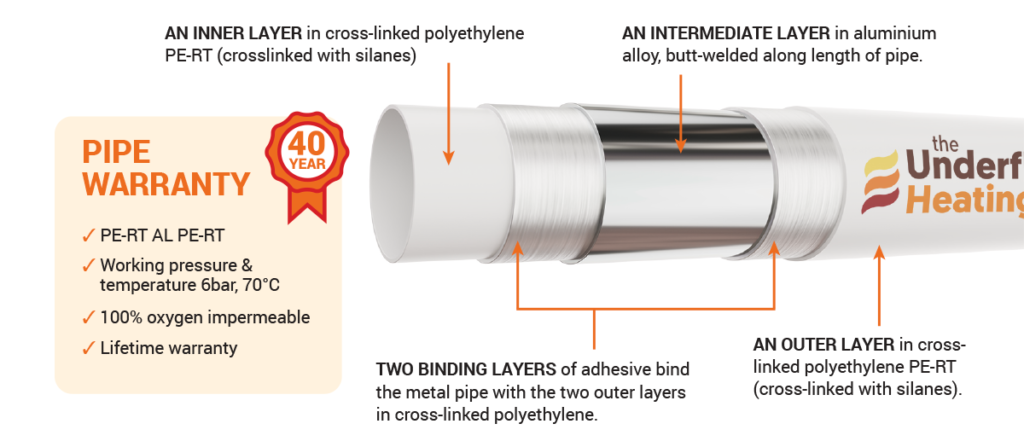

We only use high quality European standard Pert-Al-Pert pipe in all our water underfloor heating systems.

Our range of pert-al-pert pipe is manufactured to ISO9001 European standards ensuring a lifetime of outstanding performance & reliability.

Five layer 16mm pert-al-pert pipe is used in all of our warm water underfloor heating kits and offers unrivaled suitability for underfloor heating by combining the best elements of a plastic and metal pipe into one product.

The aluminium core provides strength and importantly acts as an oxygen barrier to stop the ingress of oxygen into the system causing premature wear (corrosion) to the manifold. The aluminium layer also makes the pipe form-stable, making it very easy to work with by eliminating spring back for easier installation.

-

Manuals & Guides

Download our handy installation PDF guides

Download Manuals ››

for help with your underfloor heating installation... -

Confused??

New to underfloor heating? Not sure

Learn more ››

where to begin?

We've got you covered... -

Get a Quote...

Get a full and detailed quotation for your

Get a Quote ››

complete underfloor heating system... -

Need Help?

Just get in touch and one of our friendly members of

Get in touch with us ››

staff will help answer any questions you may have...

Trade Discounts

Trade Discounts  Fast Delivery

Fast Delivery  Rated Excellent

Rated Excellent  Simple Returns

Simple Returns  100% Secure Shopping

100% Secure Shopping